Visual Inspection for Surface Quality

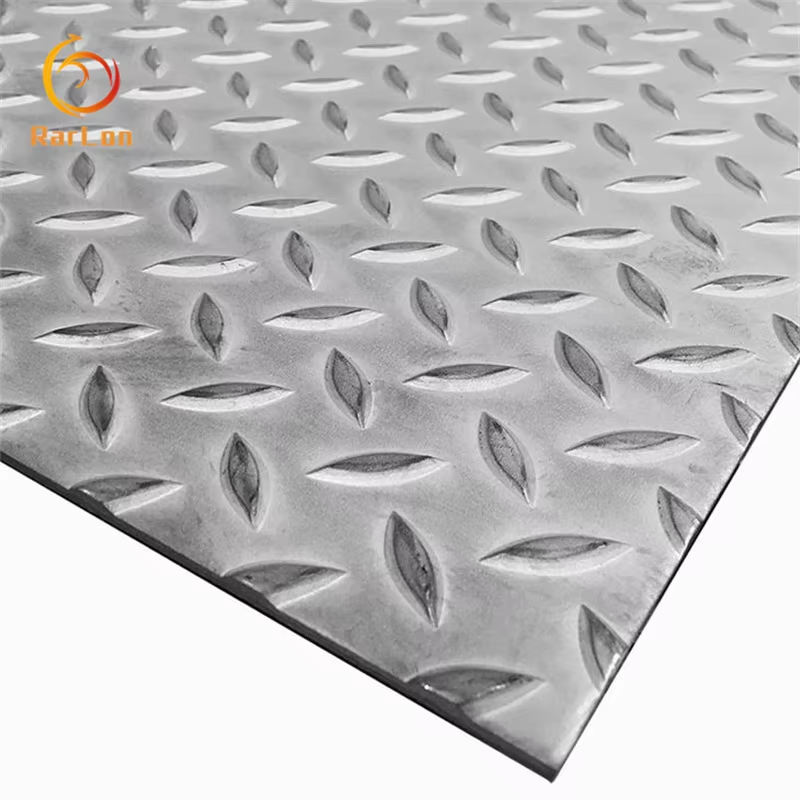

When trying to identify a high-quality hot rolled mild steel sheet, start with a thorough visual examination. Look for a smooth, uniform surface free from major imperfections like cracks, pits, or excessive scaling. A good sheet should have a consistent grayish-blue oxide layer, which is normal due to the hot rolling process, but it shouldn't be flaky or rusted. For instance, at Rarlon Steel, our hot rolled mild steel sheets undergo rigorous surface checks to ensure they meet industry standards, providing a clean finish that minimizes the need for additional processing. This step helps you avoid sheets with hidden defects that could compromise structural integrity in applications like construction or automotive parts.

Assessing Physical and Mechanical Properties

Next, evaluate the physical characteristics of the hot rolled mild steel sheet to ensure it meets your needs. Key properties include thickness uniformity, strength, and ductility. Use simple tools like calipers to check for consistent thickness across the sheet, as variations can indicate poor manufacturing. Additionally, consider the steel's tensile strength and yield point—a quality sheet should bend without cracking and have a balanced hardness for easy welding and forming. Rarlon Steel's products, for example, are tested for these mechanical properties to deliver reliable performance in various environments, making them ideal for projects that require durability and flexibility. Remember, a high-quality hot rolled mild steel sheet should exhibit these traits to withstand stress and last longer.

Verifying Certifications and Standards

To further identify a superior hot rolled mild steel sheet, always check for relevant certifications and compliance with international standards. Look for marks like ASTM A36 or ISO 9001, which guarantee that the steel has been produced under strict quality controls. These certifications ensure the material's chemical composition, such as low carbon content, is optimized for mild steel applications. At Rarlon Steel, we provide detailed documentation and adhere to global standards, so our sheets are traceable and verified for safety. This step is crucial for industries like manufacturing or infrastructure, where using certified materials reduces risks and ensures compliance with regulations.

Practical Testing and Supplier Evaluation

Finally, perform practical tests and assess the supplier's reputation to confirm the quality of a hot rolled mild steel sheet. Simple on-site tests, such as a bend test or spark test, can reveal inconsistencies in the steel's composition. Also, consider the supplier's track record—reputable companies like Rarlon Steel offer transparency in their processes, including customer reviews and after-sales support. By choosing a trusted supplier, you can access sheets that are consistently high-quality, with features like precise dimensions and excellent weldability. This holistic approach helps you make an informed decision, ensuring that the hot rolled mild steel sheet you select will perform reliably in real-world applications.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

SQ

SQ

HU

HU

MT

MT

TH

TH

TR

TR

FA

FA

MS

MS

MK

MK

HY

HY

AZ

AZ

KM

KM

LA

LA

MN

MN

MY

MY

KK

KK

UZ

UZ