Superior Surface Finish and Aesthetic Advantages

How Thin Cold Rolled Steel Achieves Improved Surface Finish

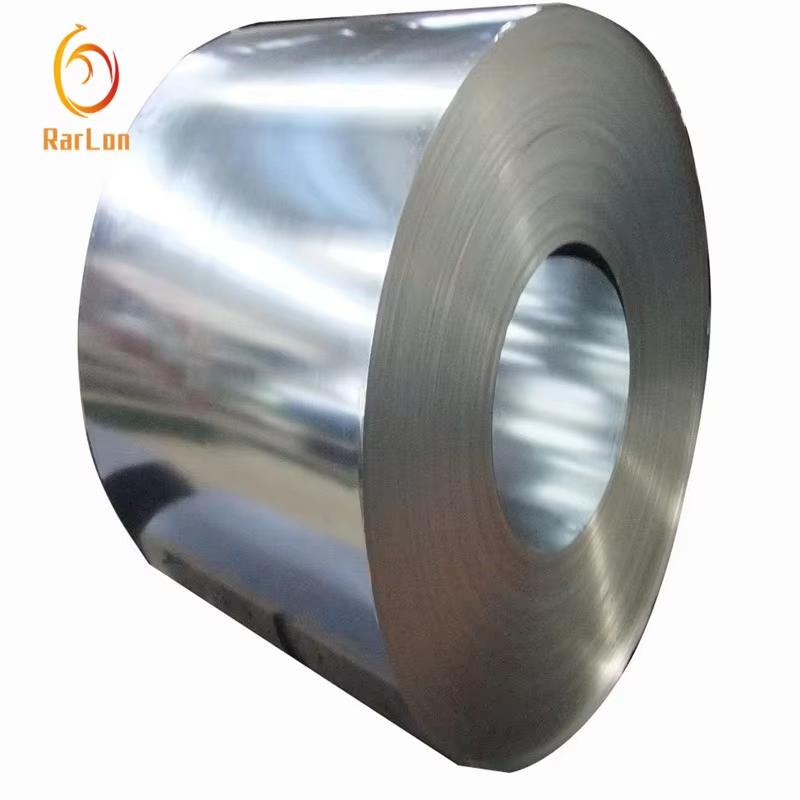

Cold rolling works by pressing steel between rollers while it's still at normal temperatures. The result? A much smoother surface compared to hot rolled steel, sometimes as much as 30% less rough. Since we skip the high heat treatment, there's no scale buildup on the metal surface either. Fewer pits and cracks form during this process too. What does all this mean? Manufacturers get a nice clean finish right off the line without needing extra grinding work before they can apply paint or coatings. That saves time when making parts that need to look good for customers to see.

Surface Finish Advantages Over Hot Rolled Steel

Cold rolled steel usually has a much smoother finish compared to hot rolled alternatives. Surface roughness measurements for cold rolled typically range between 0.8 and 1.5 micrometers Ra, while hot rolled steel tends to be much rougher at around 12 to 25 micrometers Ra. Because there's no heat involved during processing, cold rolling maintains the metal's structural properties better and allows for much tighter control over thickness specifications, about plus or minus 0.001 inches versus plus or minus 0.01 inches for hot rolled steel. These tighter tolerances mean less wasted material during production runs. The improved accuracy also makes cold rolled steel ideal for applications where appearance matters a lot, such as building facades, decorative metalwork, and products that consumers actually see and touch regularly.

Role of Surface Quality in Metal Furniture and Home Appliances

In appliances, cold rolled steel’s micro-smooth surfaces improve paint adhesion by 40%, reducing coating failures caused by substrate irregularities. For furniture, its inherent reflectivity allows for thinner protective finishes while maintaining corrosion resistance, supporting sleek, modern designs. Manufacturers report 25% faster production cycles due to reduced post-processing needs.

Precision, Dimensional Accuracy, and Consistency

Precise Dimensional Control and Tight Tolerances in Manufacturing

The cold rolling process can actually reduce material thickness by as much as 90%, yet still keep things pretty uniform throughout the sheet metal. When talking about tolerances, we're looking at something like plus or minus 0.001 inches, which is why manufacturers rely on cold rolled steel for those really precise components. Think about car body panels or cases for electronics equipment. Even tiny variations here can cause big headaches during assembly time. Modern day rolling mills work their magic by applying just the right amount of pressure to smooth out all that wavy texture and irregular surface finish that comes standard with hot rolled steel products instead.

Enhanced Strength and Hardness with Work Hardening

Work Hardening During the Cold Rolling Process

During cold rolling, plastic deformation increases dislocation density by ~15–20%, producing strain hardening that boosts yield strength without alloying elements. While this improves mechanical performance, it reduces elongation capacity. Designers account for this limitation in components like automotive seat frames, where consistent load response is crucial.

Impact on Durability in Automotive and Appliance Applications

Work-hardened cold rolled steel offers 3–5x greater wear resistance in high-friction environments. Components such as refrigerator hinges and car door mechanisms benefit from a hard surface layer combined with ductile core properties, meeting ISO 9001 durability benchmarks with 40% less material thickness.

Balancing Increased Strength With Reduced Ductility

Although cold rolling increases strength by 25–30%, it reduces elongation by approximately 50%. To manage this trade-off, engineers use selective annealing—restoring ductility in bending zones while retaining rigidity in load-bearing areas. This approach is commonly applied in washing machine drums and other complex formed parts.

Formability and Manufacturing Flexibility

How Thinness Enables Complex Shaping in Production

Thin cold rolled steel usually comes in at around 0.15 to 2.0 mm thick, which makes it possible to create complex shapes that just wouldn't work with thicker metals. The material can handle really tight bends and deep drawing operations without cracking, making it a great choice for things like electrical boxes and car parts. Some research from last year actually showed something interesting too. When manufacturers switched from hot rolled to this thinner cold rolled option, they saw about an 18% drop in tool wear during stamping processes. That kind of durability improvement matters a lot in production environments where equipment costs add up fast.

Understanding Ductility Trade-Offs After Cold Working

Cold rolling enhances strength but reduces ductility by up to 40%. Manufacturers mitigate this through controlled annealing, restoring partial malleability for secondary forming operations. This hybrid strategy supports parts requiring both rigidity and localized flexibility, such as reinforced appliance hinges.

Application in High-Precision Components Across Industries

Industries including aerospace, medical devices, and electronics rely on thin cold rolled steel for its dimensional stability and formability:

- Automotive: Fuel injection rails with 0.2 mm wall tolerances

- Electronics: EMI shielding cans with complex fold patterns

- HVAC: Custom ductwork adapters requiring airtight seams

Manufacturers using flexible manufacturing systems (FMS) report 20–30% faster product changeovers when working with thin cold rolled steel, improving responsiveness to market demands.

Thin Cold Rolled Steel vs. Hot Rolled: Performance and Applications

Key Differences in Processing and Final Properties

Cold rolled steel gets worked at normal temperatures which gives it much smoother surfaces around 15% more reflective than regular stuff. The dimensions are also way tighter with just plus or minus 0.001 inches compared to the 0.01 inch range we see with hot rolled versions. What makes cold rolling special is how it boosts tensile strength all the way up to about 85,000 pounds per square inch while hot rolled only hits around 67,000. This happens because of something called work hardening that manufacturers have observed time and again across the industry. On the downside though, when looking at how much it can stretch before breaking, cold rolled steel falls short at 28% elongation versus 36% for hot rolled material. That means it's not really suitable for parts that need to bend or deform significantly during use.

Cost-Benefit Analysis for Long-Term Applications

Cold rolled steel does come with a price tag about 37% higher than alternatives upfront, but what many manufacturers find is that it lasts much longer when exposed to harsh conditions. This makes sense especially in coastal areas where salt air eats away at materials so quickly. For appliance companies, there's another benefit too. They spend around $8 to $12 less on each finished product because the material requires almost no preparation before painting or coating. The surface is already smooth and ready to go. That said, when looking at massive production runs exceeding fifty tons per week, most businesses still opt for hot rolled steel simply because suppliers can deliver it within just 48 hours. Time really matters in these big operations where delays cost money.

When Hot Rolled Steel Might Still Be Preferable

Hot rolled steel remains more economical for temporary structures—used in 87% of scaffolding systems—and high-temperature environments where cold worked steel loses 40% of its hardness. Its superior weldability also benefits farm equipment manufacturing, requiring 23% fewer post-weld treatments according to industry studies.

Frequently Asked Questions

What is the main difference between cold rolled and hot rolled steel?

Cold rolled steel is processed at normal temperatures, resulting in smoother surfaces and tighter dimensional tolerances compared to hot rolled steel, which is processed at high temperatures.

Why is cold rolled steel preferred for automotive applications?

Cold rolled steel offers superior dimensional accuracy and tensile strength, making it ideal for automotive applications where precision and durability are crucial.

How does cold rolling improve surface finish?

The cold rolling process smooths out the texture and eliminates scale buildup on the steel surface, resulting in a cleaner finish.

Can cold rolled steel be used for high-temperature applications?

Cold rolled steel is not usually recommended for high-temperature applications as it can lose up to 40% of its hardness. Hot rolled steel is often preferred in such environments.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

SQ

SQ

HU

HU

MT

MT

TH

TH

TR

TR

FA

FA

MS

MS

MK

MK

HY

HY

AZ

AZ

KM

KM

LA

LA

MN

MN

MY

MY

KK

KK

UZ

UZ