Understanding Angle Bars and Their Role in Structural Support

Angle bars, sometimes called L-brackets or angle steel, form an essential part of many construction jobs where structures need extra support. The L shape these bars come in is pretty standard across the industry, usually fabricated from either steel or aluminum. What makes them stand out is how they handle weight so well without needing excessive materials. Some research indicates that when used correctly, angle bars actually distribute loads better than flat metal pieces, with improvements ranging around 30 to 40 percent. That's why contractors keep coming back to them whenever building something that demands both solid strength and accurate measurements.

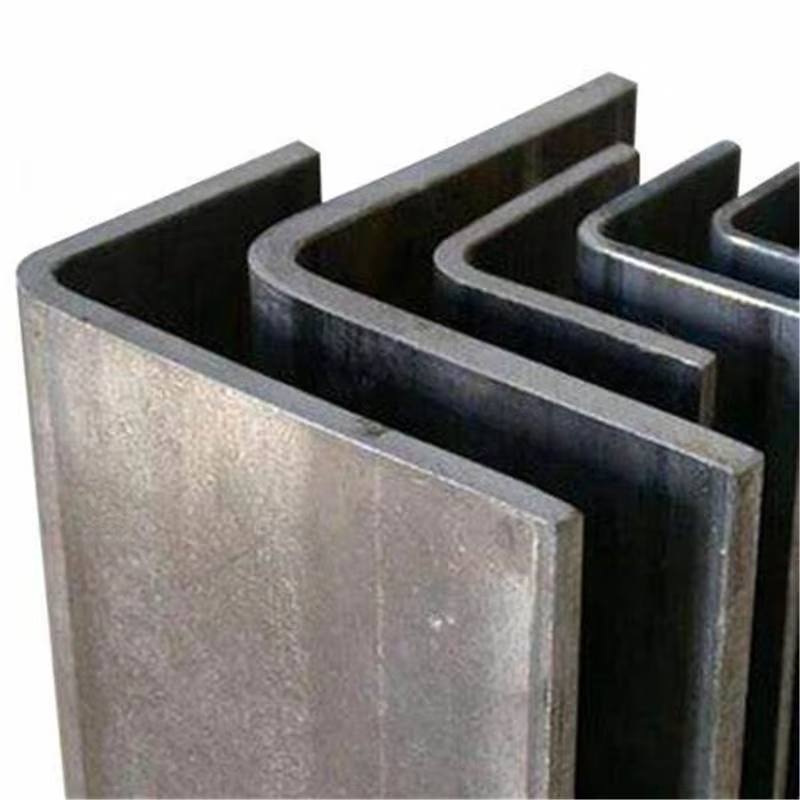

What Is an Angle Bar? Definition and Basic Function

Angle bars are basically metal pieces where two sides come together at right angles, creating a strong structural component that can handle different types of force including tension, bending, and shearing. According to recent industry findings, the way these bars are shaped lets load distribute better between both sides, which cuts down on stress points by around a quarter when compared to flat support structures. When it comes to thickness options, most manufacturers offer materials starting at about 3 millimeters thick for lighter projects all the way up to 20 millimeters for serious industrial workloads.

Common Applications of Angle Steel in Construction and Engineering

From reinforcing concrete slabs to stabilizing transmission towers, angle bars serve diverse roles. Key uses include:

- Framing systems: Creating durable skeletons for warehouses and high-rises

- Bracing: Preventing lateral shifts in earthquake-prone regions (used in 78% of seismic retrofits per 2022 engineering surveys)

- Bridge construction: A case study demonstrated galvanized angle bars extended a suspension bridge’s service life by 15 years through enhanced corrosion resistance.

Types of Angle Bars: Equal vs. Unequal Legs

Angle bars with equal legs, like those measuring 50 by 50 by 5 millimeters, spread weight evenly across both sides. This makes them great choices for things that need to hold stuff uniformly, think shelves or storage racks. When dealing with structures where weight isn't balanced on all sides, unequal leg versions become important. Take something like a 100x75x6 mm bar - these can handle twisting forces about 20% better than their equal counterparts in situations such as cantilevered walkways. Most engineers will go for unequal legs whenever they see load ratios going above 3 parts vertical to 1 part horizontal. The American Society for Testing and Materials has actually put this recommendation into their A36 steel specifications, which is something every structural designer should keep in mind during planning stages.

Key Selection Criteria: Size, Dimensions, and Industry Standards

How Angle Bar Dimensions Affect Structural Stability

The length, thickness, and overall cross section of an angle bar really matter when it comes to how well it can spread out loads across different points. When we talk about longer legs on these bars, they actually stand up better against those pesky bending forces that try to warp things out of shape. And if we compare different thicknesses, say something like 10 mm versus just 6 mm, the thicker ones generally handle straight line forces much better too. Some tests show around a 40% improvement in certain cases. But here's what happens when people get the measurements wrong. If the dimensions don't match properly, stress builds up unevenly right at the connection points between components. This kind of imbalance makes the whole system wear out faster over time, especially in structures that go through lots of repeated movements or weight shifts, such as those big metal shelves used in warehouses and factories everywhere.

Choosing Between Equal and Unequal Angle Bars Based on Load Needs

Equal angle bars like those measuring 50x50x5 mm work really well when dealing with balanced loads. They're commonly used for things like frame bracing or supporting trusses where weight is distributed evenly across both sides. On the other hand, unequal leg angles such as 100x75x8 mm handle situations where weights aren't balanced. These are often seen on crane arms or cantilever platforms. The longer leg takes most of the shear force, while the shorter one helps save space without getting in the way too much. When talking about dynamic loads over 5 kN per square meter, these unequal designs actually perform better. Tests show they can cut down on bending by around 18 to 22 percent compared to regular equal profile bars that weigh about the same. That makes them a smart choice for applications where structural integrity matters most.

Relevant Standards (ASTM, ISO) for Angle Bar for Structural Support

Meeting standards like ASTM A36 for carbon steel or ASTM A992 for high strength materials makes sure we get reliable yield strength numbers between 250 to 345 MPa while maintaining good weld properties needed for building frames. The ISO 657-1 standard actually sets those hot rolled angle tolerances at around plus or minus 1.5% for leg lengths. This matters because when parts don't fit together properly during bolted assemblies, everything gets messed up. For structures near saltwater or in coastal areas, engineers typically specify ASTM A588 grades instead. These materials resist rust much better than regular steel. We test this corrosion resistance using salt spray tests according to ISO 9227 standards. Most projects need at least 720 hours of exposure before they pass quality checks. It's all about making sure buildings last longer without constant maintenance headaches.

Stress Distribution and Safety Factors in Design

Getting the right stress distribution really depends on how thick the materials are and what kind of joints we're working with. Take those uneven leg angles, like the L4x3x1/4 type, they actually handle bending stresses better when dealing with asymmetrical loads compared to their equal leg counterparts. Most industry standards suggest keeping safety factors between 1.5 and 2.0 for structural steel parts. This extra margin helps protect against unexpected forces such as earthquakes or machinery shaking. Looking at recent research, about one out of every four angle bar failures in areas prone to strong winds can be traced back to poor manufacturing tolerances. That statistic alone makes a compelling case for paying close attention to these details during fabrication.

Material Options and Environmental Durability

Selecting the right material for angle bars requires balancing strength, environmental resilience, and cost efficiency. Industry professionals prioritize materials that meet structural demands while withstanding long-term exposure to moisture, temperature fluctuations, and chemical agents.

Steel vs. Aluminum: Strength, Weight, and Application Fit

Steel angle bars are the go-to choice for heavy load applications because of their impressive tensile strength which ranges from around 400 to 550 MPa plus they're really rigid stuff. That makes these bars perfect for building industrial frames and structures that need to resist earthquakes. Now aluminum alloys tell a different story. They weigh about 65 percent less than steel so naturally they shine in situations where weight matters most such as aircraft components or parts used on boats where standing up to saltwater corrosion becomes super important. Sure steel can handle more bending without breaking but what aluminum lacks in raw strength it makes up for in being easier to work with during complicated manufacturing processes.

Corrosion Resistance and Long-Term Performance by Material Type

What materials we pick makes all the difference when it comes to how long equipment lasts in places where corrosion is a problem. Take hot dip galvanized carbon steel for instance. This stuff can last anywhere from 15 to over 50 years along coastlines because the zinc coating acts as protection against rusting. Then there's stainless steel like grades 304 or 316 which stands up pretty well to chlorine exposure in chemical processing facilities. The downside? It costs around three to four times what regular carbon steel does. Looking at life cycle assessments tells another story too. Aluminum develops this natural oxide layer that cuts down on maintenance needs by about 40 percent compared with plain old steel in those damp, humid areas where corrosion happens faster.

Surface Treatments and Quality Assurance for Reliable Installation

When it comes to angle bars, proper surface treatment and strict quality checks just cant be skipped if we want them to last. Galvanization is still king when fighting corrosion. It coats the metal with zinc which stops rust from forming even in damp areas or near saltwater. For jobs where conditions aren't so harsh, painting with epoxy or acrylic works well enough and saves money too. Plus these coatings come in different colors so they can match whatever building or structure they're attached to. Some contractors actually prefer this option because it looks better integrated into the overall design while still offering decent protection against the elements.

The quality control process starts by checking if manufactured parts meet their size requirements. The dimensions need to match what's specified in the blueprints pretty closely too around plus or minus 2% for thickness and about 3% for length according to those ASTM standards most folks follow. Before anything gets welded together, there are special tests done to see how well materials will hold up when joined this way. These help prevent cracks from forming later on when things get stressed during normal operation. For really important structural pieces like bridge supports or buildings meant to withstand earthquakes, extra inspections happen through methods like ultrasound scans or magnetic particle checks. These catch hidden problems that simple eye exams just cant spot, which matters a lot for safety reasons obviously.

Production methods directly impact structural integrity—hot-rolled angle bars exhibit superior grain alignment for heavy loads, while cold-formed variants prioritize dimensional precision for architectural applications. Manufacturers adhering to ISO 9001 protocols consistently deliver angle steel with <0.5% deviation in yield strength, ensuring predictable performance across installations.

FAQ

What is the main purpose of angle bars in construction?

Angle bars are used to provide structural support due to their ability to handle various forces such as tension and bending effectively. They are especially beneficial in distributing loads, which improves the overall durability and safety of structures.

What are the differences between equal and unequal angle bars?

Equal angle bars distribute weight uniformly across both sides, making them ideal for balanced loads. Unequal angle bars are better suited for situations with uneven weight distribution, as they can handle twisting forces more effectively.

How do surface treatments like galvanization protect angle bars?

Surface treatments such as galvanization coat the metal with zinc, preventing rust and corrosion, especially in humid or coastal environments. This enhances the longevity and durability of angle bars in harsh conditions.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

SQ

SQ

HU

HU

MT

MT

TH

TH

TR

TR

FA

FA

MS

MS

MK

MK

HY

HY

AZ

AZ

KM

KM

LA

LA

MN

MN

MY

MY

KK

KK

UZ

UZ