ความเป็นเลิศในการผลิต: การปรับปรุงคุณสมบัติของเหล็กให้เหมาะสมสำหรับการใช้งานที่หลากหลาย

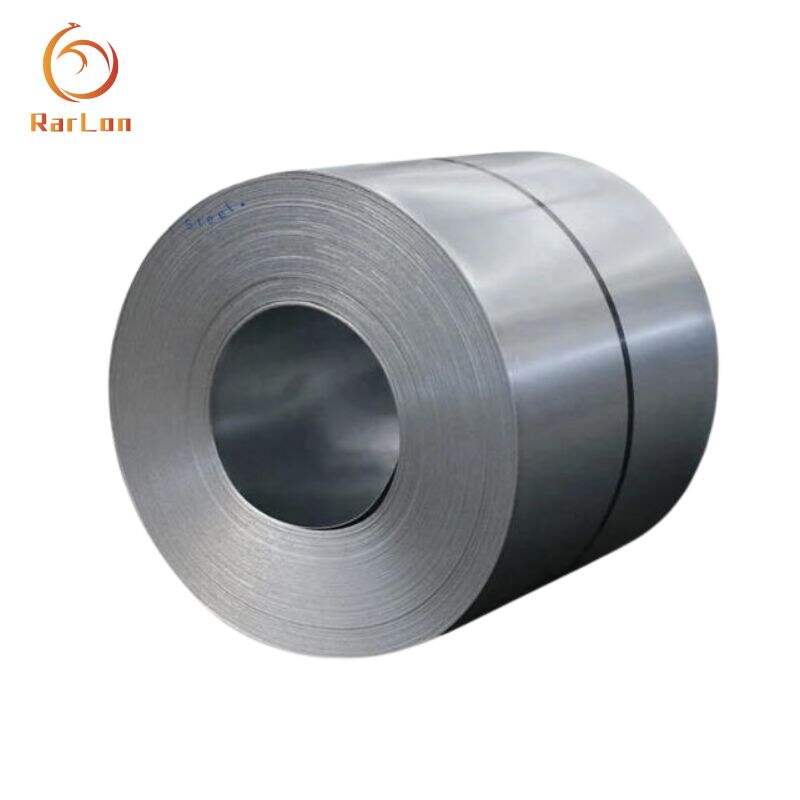

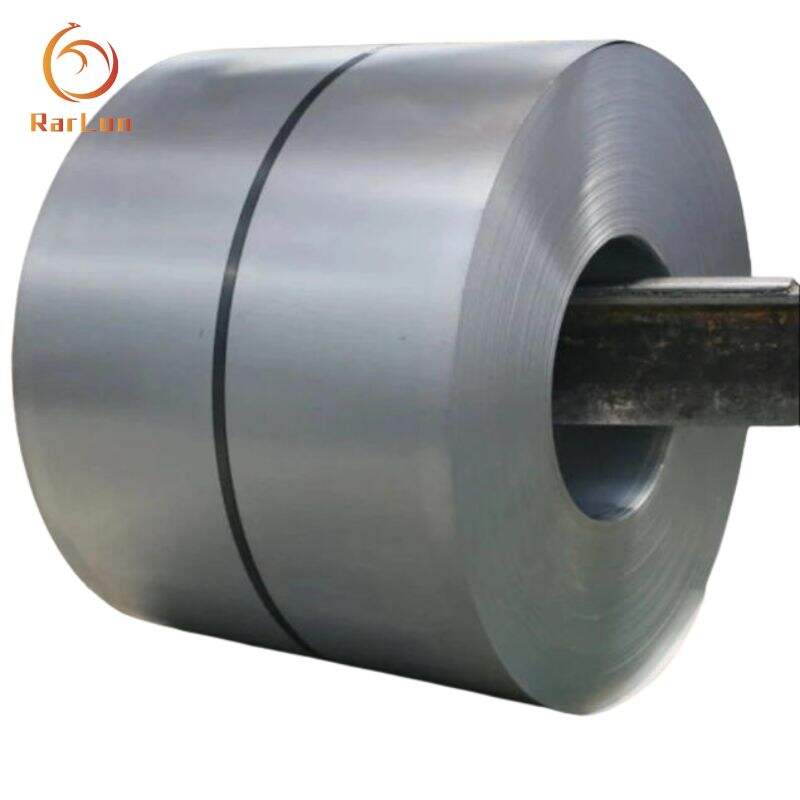

บริษัทผู้ผลิตที่มีความหลากหลายต้องการเพิ่มประสิทธิภาพคุณสมบัติของขดลวดเหล็กรีดเย็นสำหรับการใช้งานต่างๆ โดยอาศัยกระบวนการอบอ่อนของเรา ทำให้เกิดความแข็งแรงดึงดูดที่ดีขึ้นและลดความเปราะบางลง การเปลี่ยนแปลงนี้ช่วยให้ลูกค้าสามารถขยายไลน์ผลิตภัณฑ์และเข้าถึงตลาดใหม่ ๆ ได้ ส่งผลให้รายได้เพิ่มขึ้น 15% ความร่วมมือของเรายังแสดงให้เห็นถึงบทบาทสำคัญของการบำบัดวัสดุที่มีคุณภาพในการยกระดับประสิทธิภาพของผลิตภัณฑ์