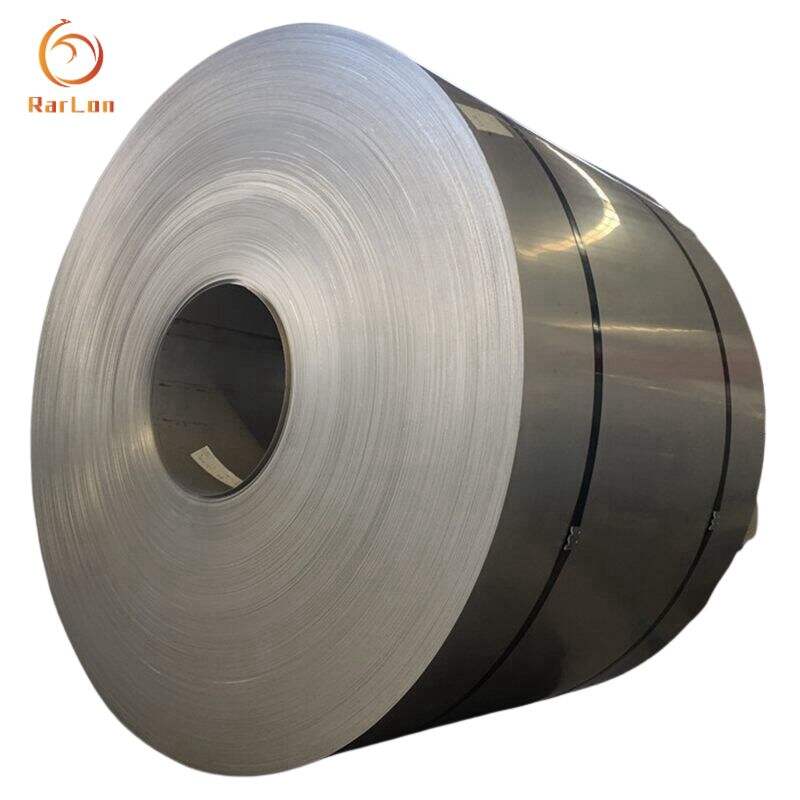

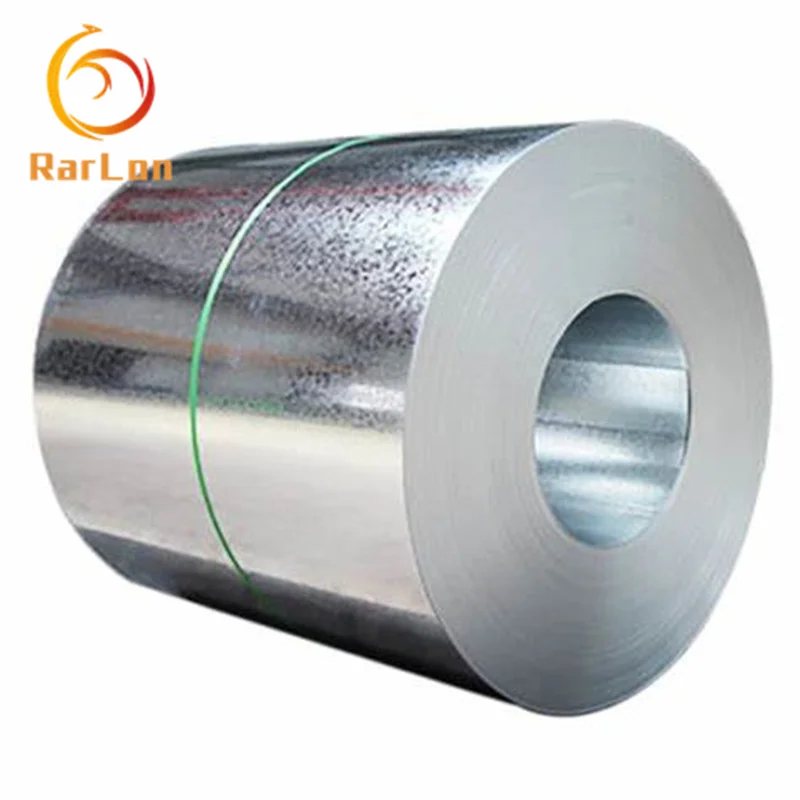

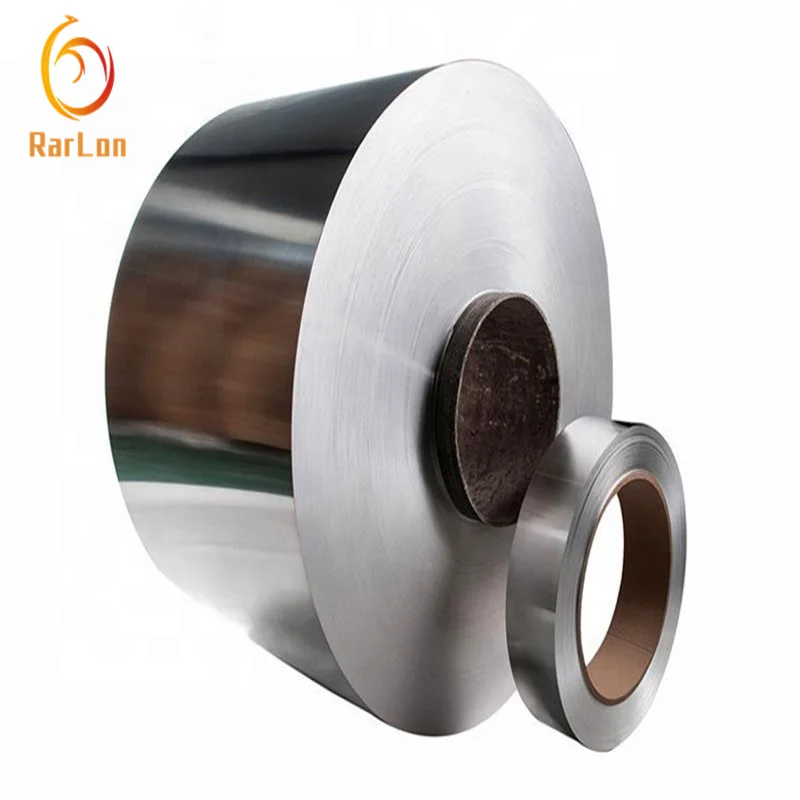

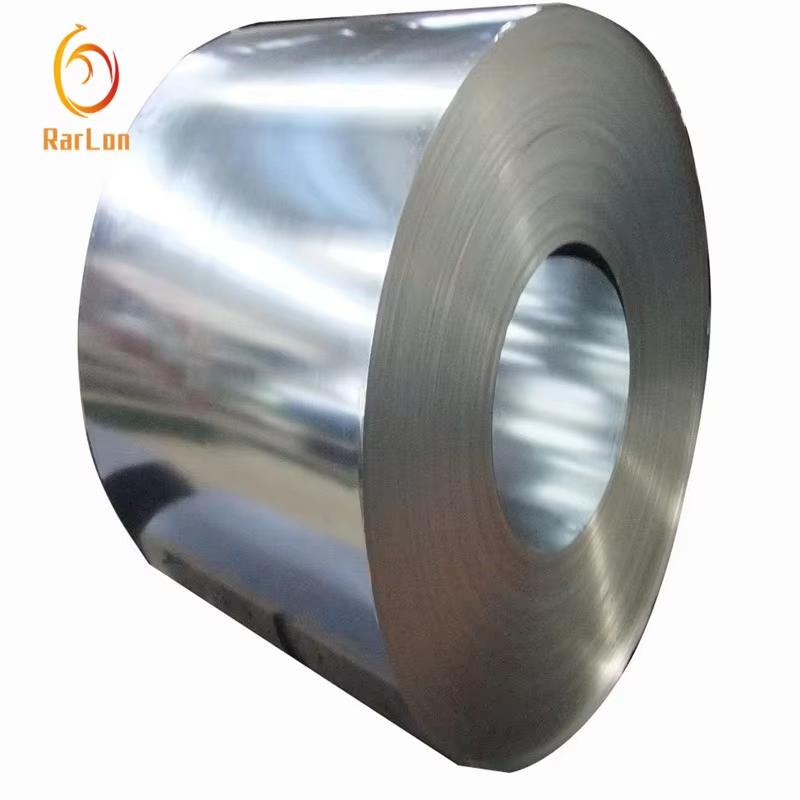

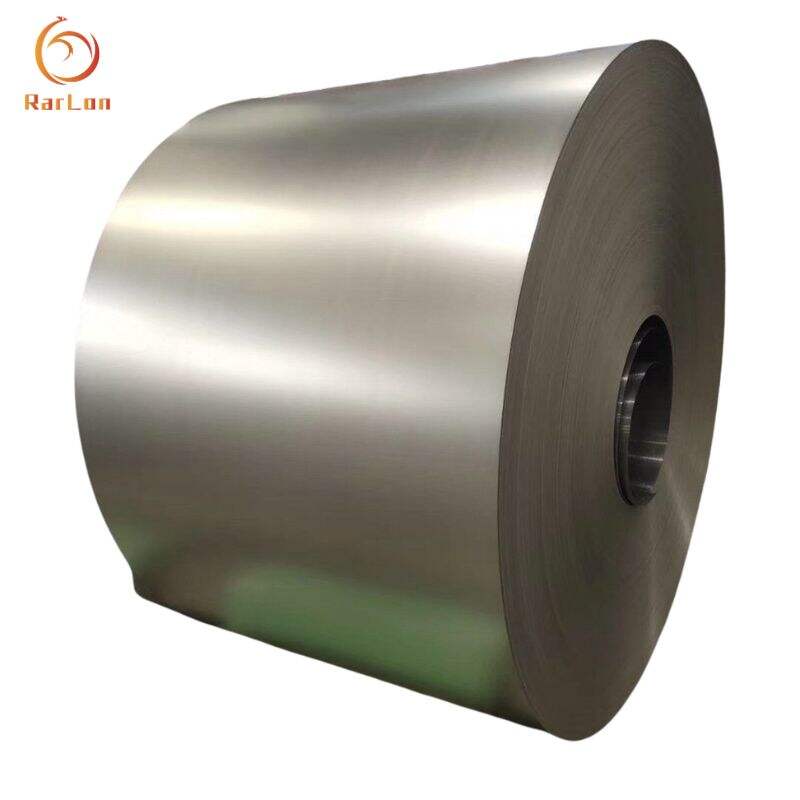

Unmatched Surface Quality Control for Cold Rolled Steel Coils

At China Rarlon Group Limited, we leverage our extensive experience since 2008 to ensure unparalleled surface quality control in our cold rolled steel coils. Our rigorous quality assurance processes involve advanced testing methods and state-of-the-art technology to monitor surface imperfections, thickness variations, and mechanical properties. This dedication to quality not only enhances the aesthetic appeal of our products but also ensures their durability and performance in various applications. Our commitment to excellence has positioned us as a trusted supplier in the international market, meeting the diverse needs of our clients across different industries.

Get A Quote

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

SQ

SQ

HU

HU

MT

MT

TH

TH

TR

TR

FA

FA

MS

MS

MK

MK

HY

HY

AZ

AZ

KM

KM

LA

LA

MN

MN

MY

MY

KK

KK

UZ

UZ