The Unmatched Benefits of Hot Rolled Steel Plates

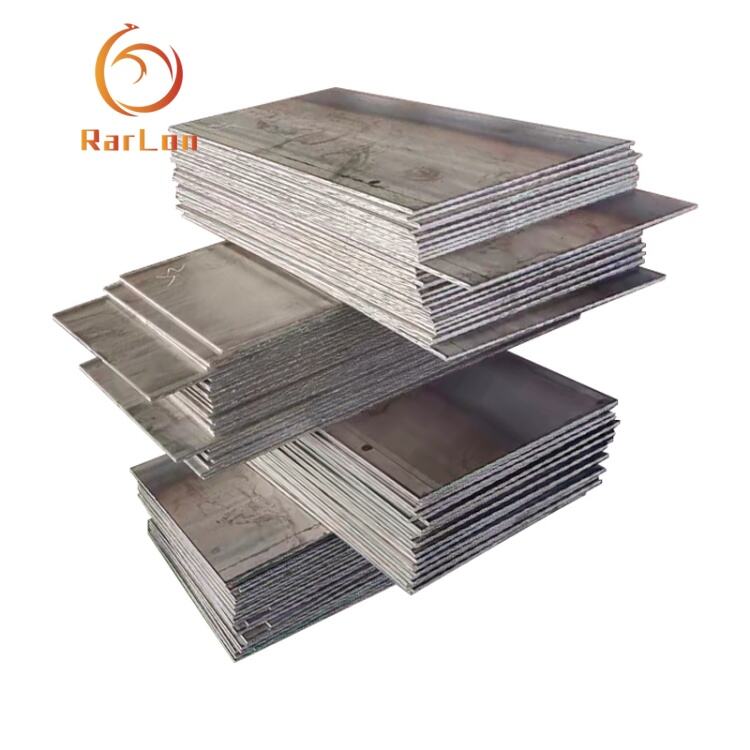

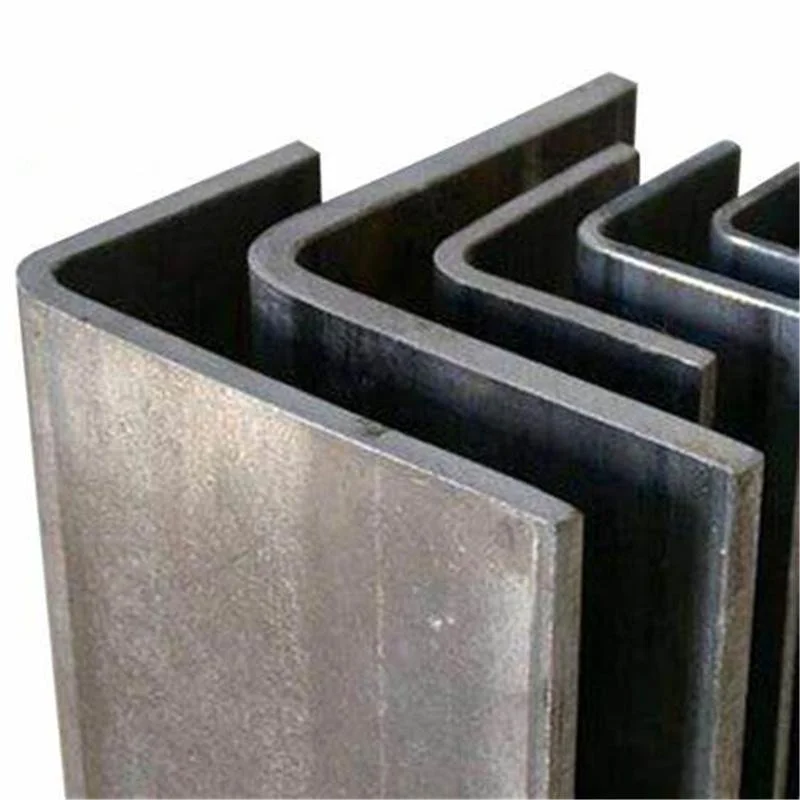

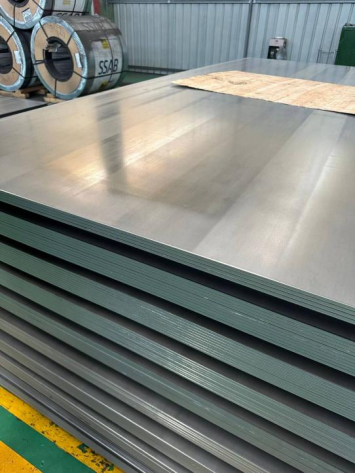

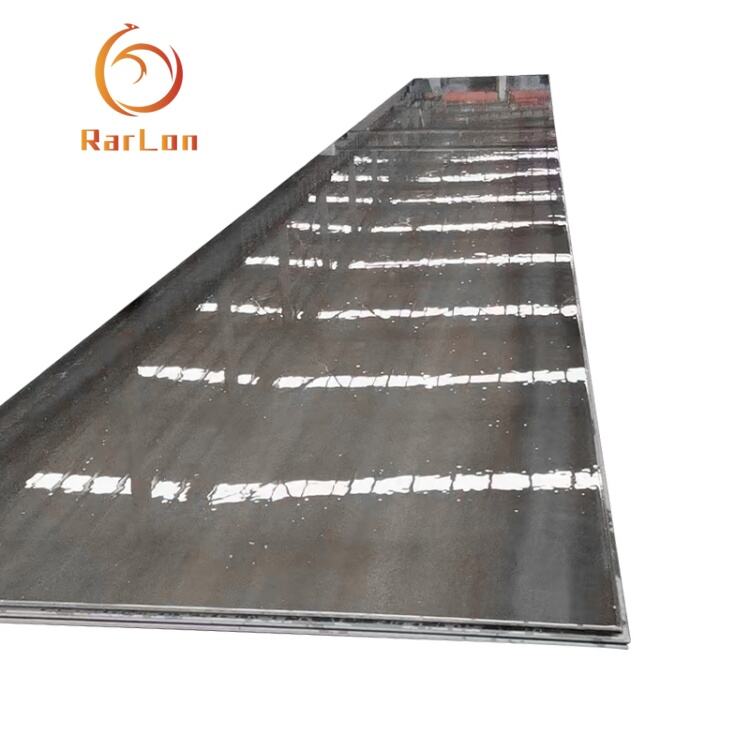

Hot rolled steel plates are essential in various industries due to their strength, versatility, and cost-effectiveness. At China Rarlon Group Limited, we specialize in high-quality hot rolled steel plates that offer superior mechanical properties, making them ideal for construction, manufacturing, and heavy machinery applications. Our plates are produced using advanced techniques that ensure consistency in thickness, surface finish, and dimensional accuracy. The hot rolling process enhances the material’s ductility, allowing for easier shaping and fabrication, which is crucial for meeting diverse customer requirements. Additionally, our extensive experience in international trade ensures that we can deliver these products globally with efficiency and reliability.

Get A Quote

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

SQ

SQ

HU

HU

MT

MT

TH

TH

TR

TR

FA

FA

MS

MS

MK

MK

HY

HY

AZ

AZ

KM

KM

LA

LA

MN

MN

MY

MY

KK

KK

UZ

UZ