The Superior Choice for W Beam Surface Coating

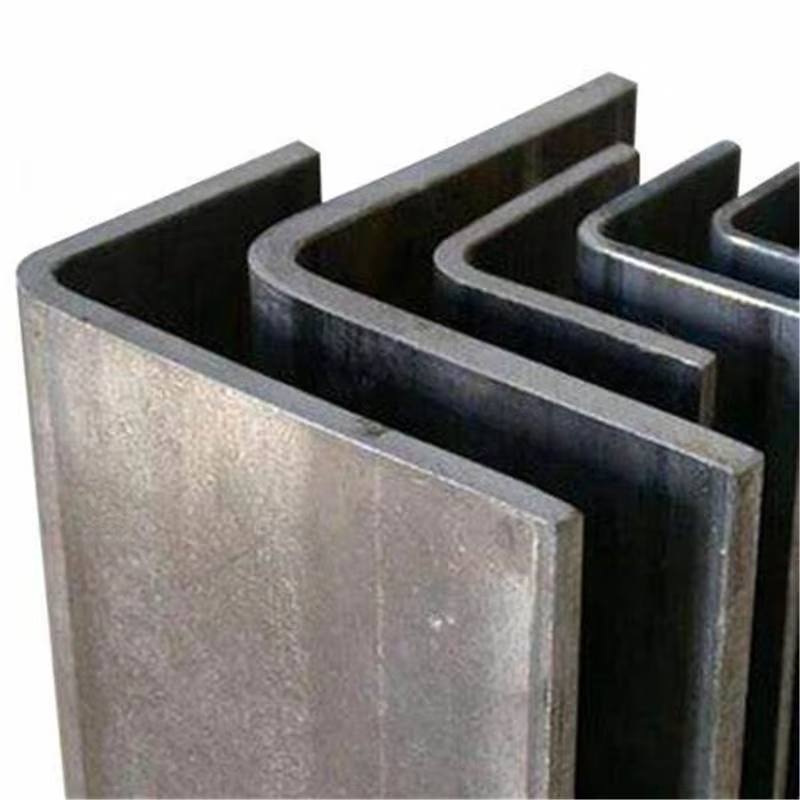

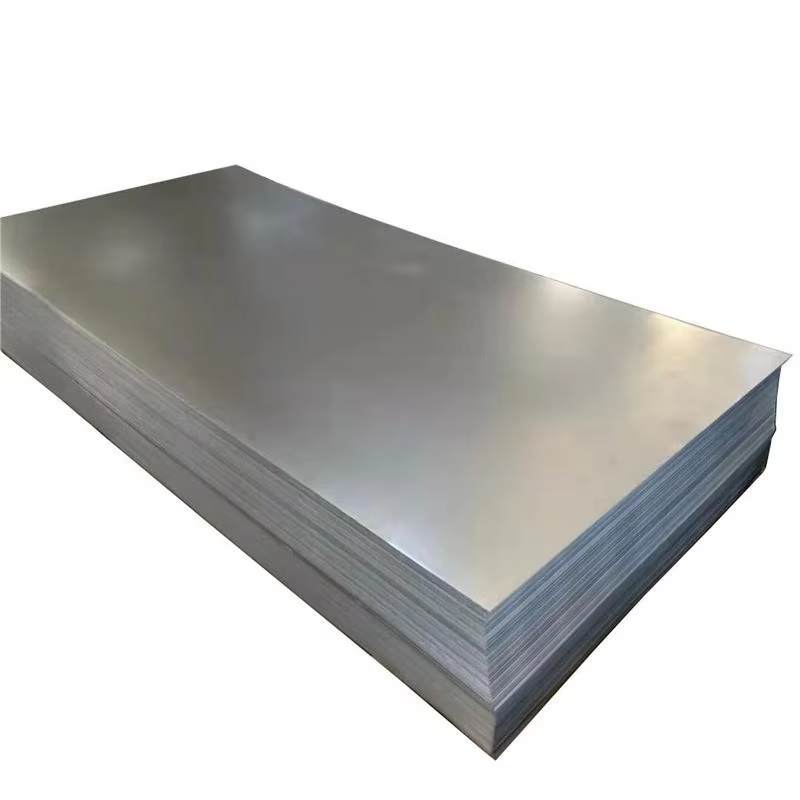

W Beam Surface Coating is a revolutionary solution offered by China Rarlon Group Limited, designed to enhance the durability and performance of steel products in various applications. Our advanced coating technology provides superior corrosion resistance, ensuring that your W beams withstand harsh environmental conditions without compromising structural integrity. The coating process enhances the aesthetic appeal and longevity of the beams, making them ideal for construction projects demanding high standards. Additionally, our commitment to quality and innovation means that we utilize the latest technologies and materials, ensuring that our W Beam Surface Coating meets international standards. By choosing our coating solutions, clients can expect reduced maintenance costs, extended product life, and improved performance, ultimately leading to increased project efficiency and satisfaction.

Get A Quote

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

SQ

SQ

HU

HU

MT

MT

TH

TH

TR

TR

FA

FA

MS

MS

MK

MK

HY

HY

AZ

AZ

KM

KM

LA

LA

MN

MN

MY

MY

KK

KK

UZ

UZ