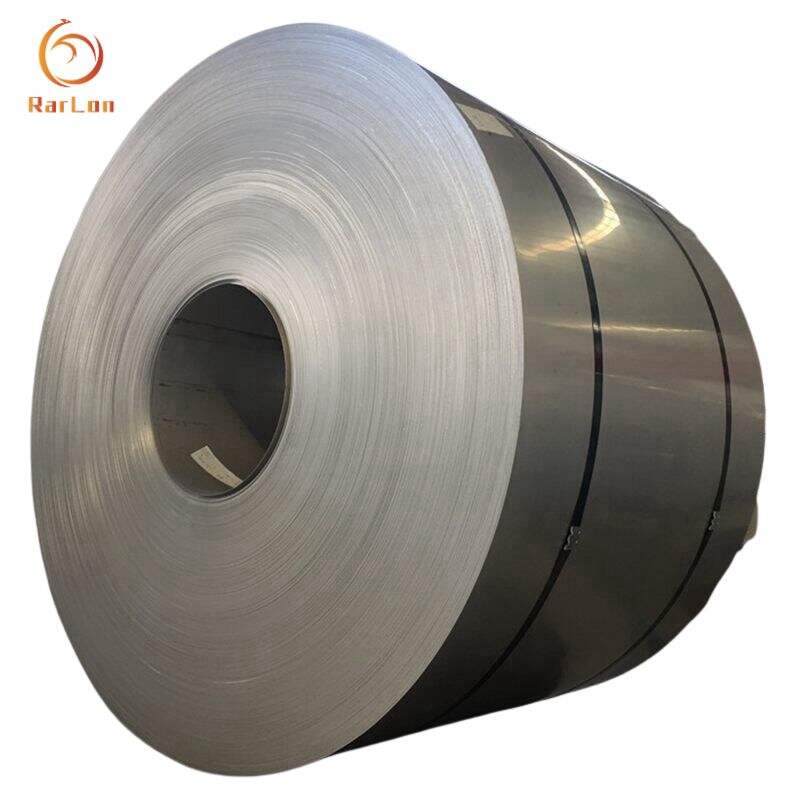

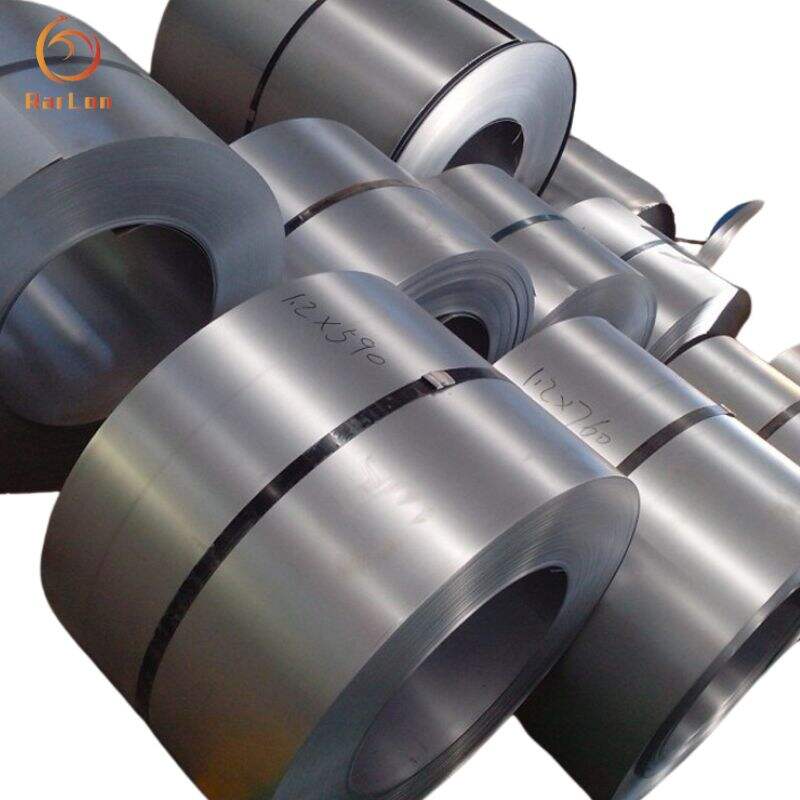

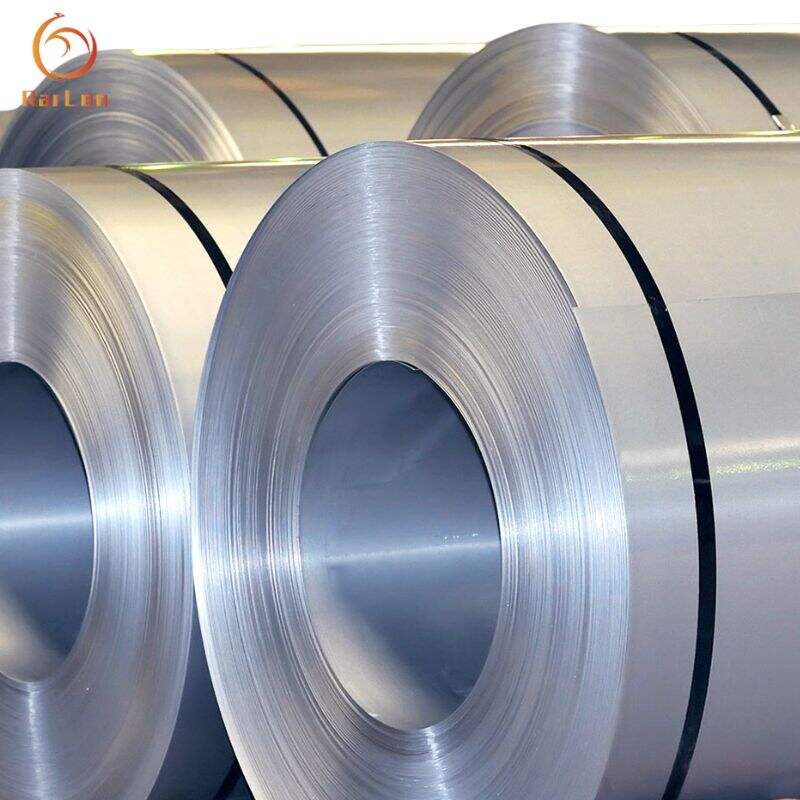

Steel that rolls cold with anti corrosion coatings shows advanced engineering excellence within our sector. At China Rarlon Group Limited we have controlled anti corrosion coated cold rolled steel perfected within its sector to controlled rolled sheets and coils that receive comprehensive quality evaluations. Every stage within the coatings process employ advanced corrosion techniques that incorporate adhesion and durability to withstand the coated steel to detailed specification environmental elements. Throughout the steel value adding process, to cold rolling, and up to the coatings process completion, to comprehensive quality standards. Client requires steels to be aesthetically pleasing with all diverse applications including construction, automotive, and manufacturing. Performance with aesthetically cold rolled steel meet within all client performance standards with lower value adding processes. This commitment advanced engineering assures all valued client processes are lower value adding processes high performance steel is to maintain the highest performance standards within all global climates.

1116, Huaying Building Center Avenue, Tianjin Airport

+86-189 20578670

Copyright © China Rarlon Group Limited All Rights Reserved - Privacy Policy