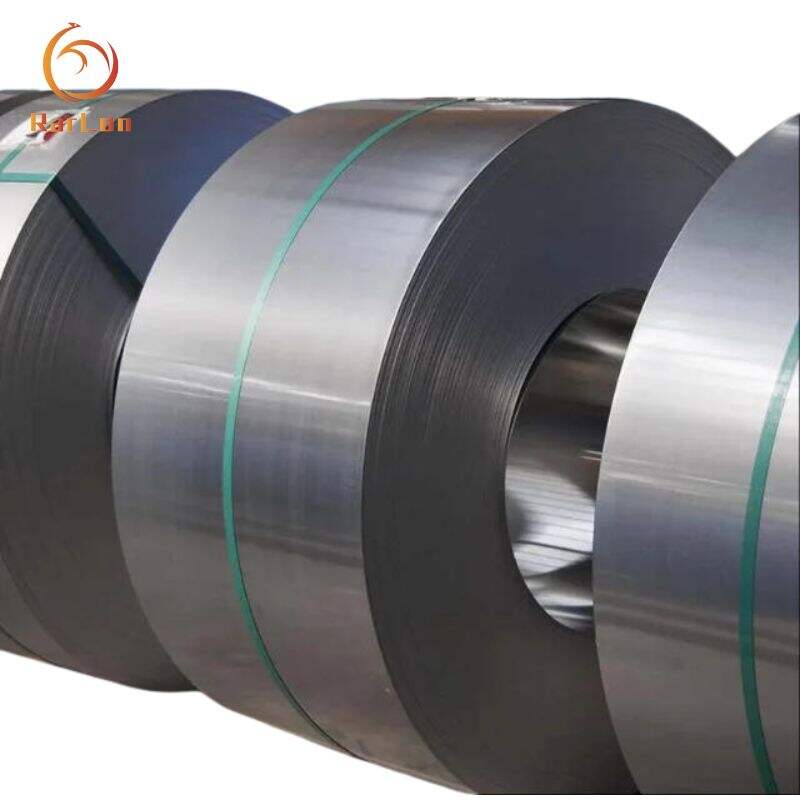

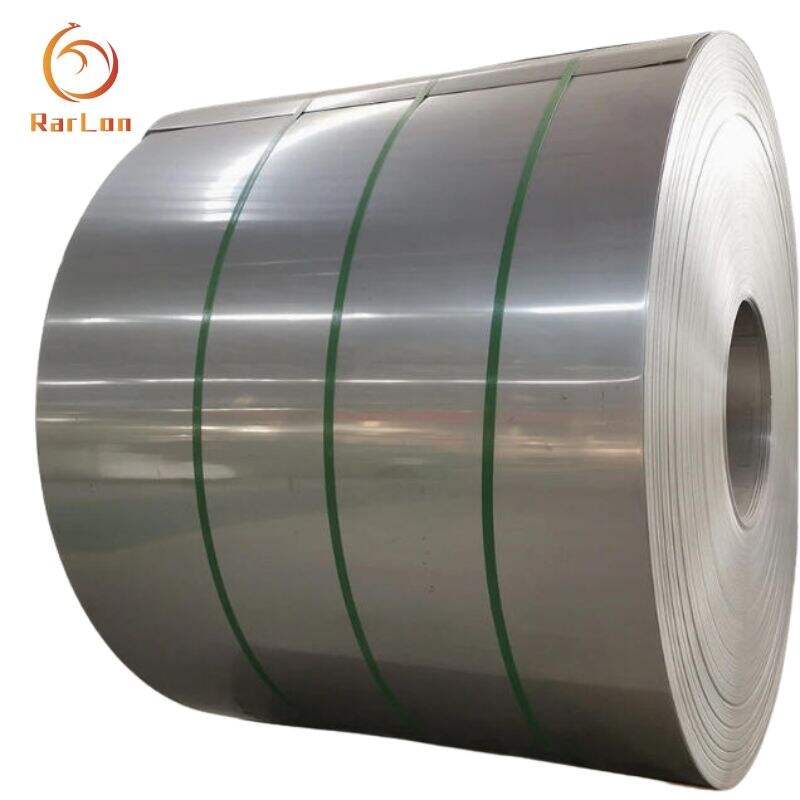

Unmatched Quality and Performance of Cold Rolled Steel Coils for Stamping

At China Rarlon Group Limited, our cold rolled steel coils for stamping are engineered to deliver superior performance and durability. These coils undergo a meticulous manufacturing process that enhances their mechanical properties, ensuring they can withstand the rigors of stamping applications. Our commitment to quality is evident in every coil we produce, as we utilize advanced technology and stringent quality control measures. With a focus on customer satisfaction, our cold rolled steel coils offer exceptional formability, precision, and surface finish, making them ideal for a wide range of industries including automotive, electronics, and construction. Choose our products for reliable performance and outstanding value.

Get A Quote