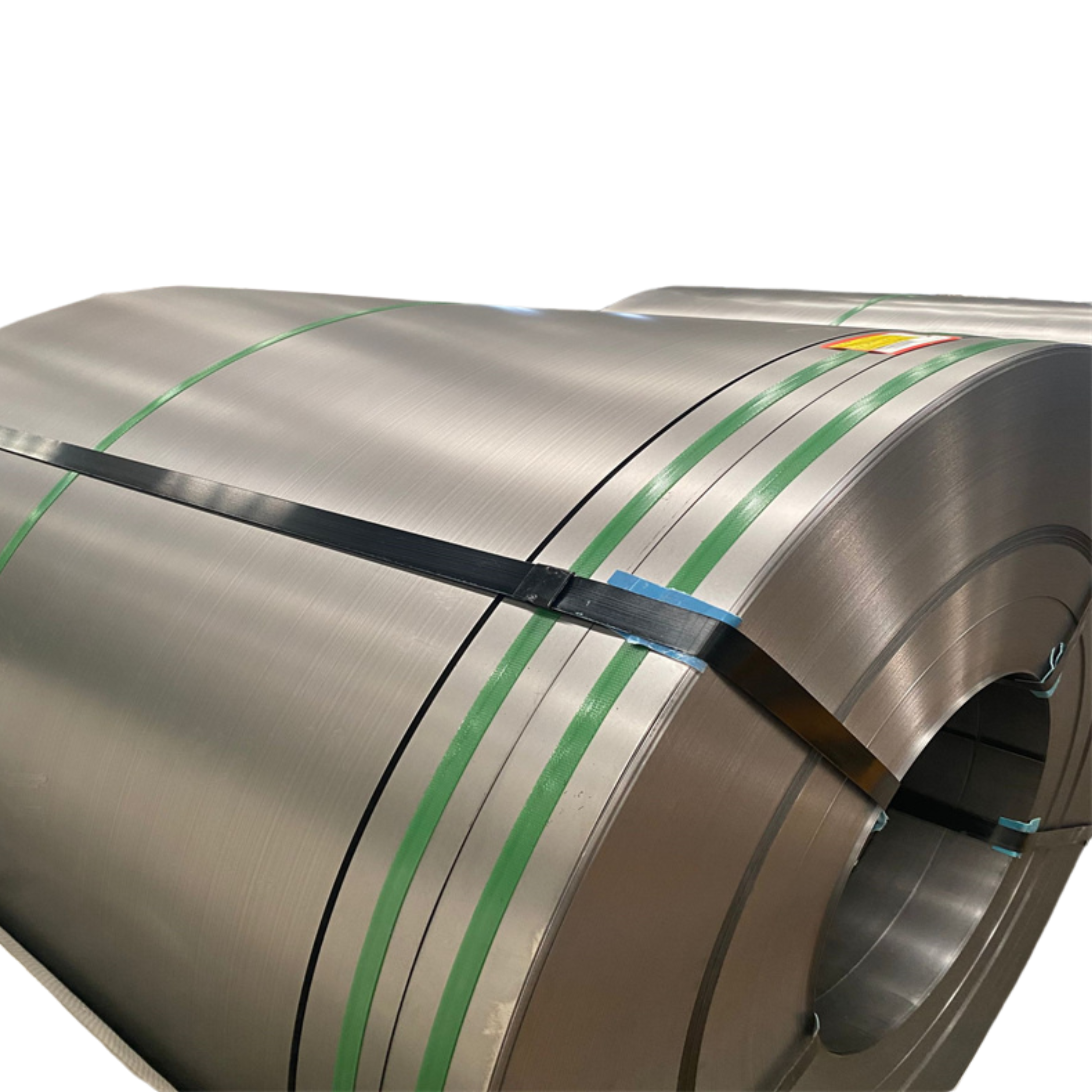

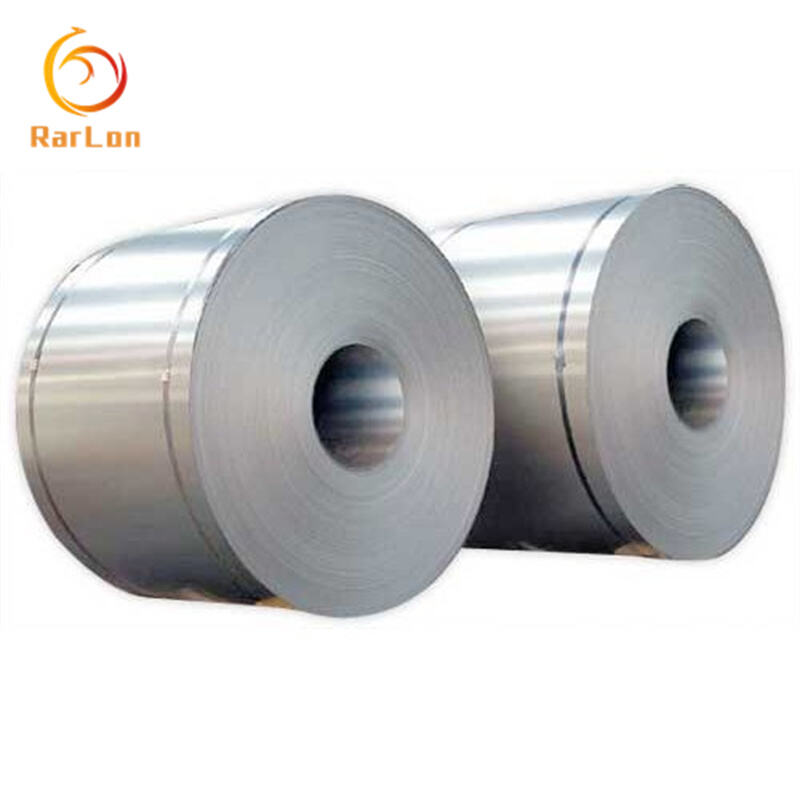

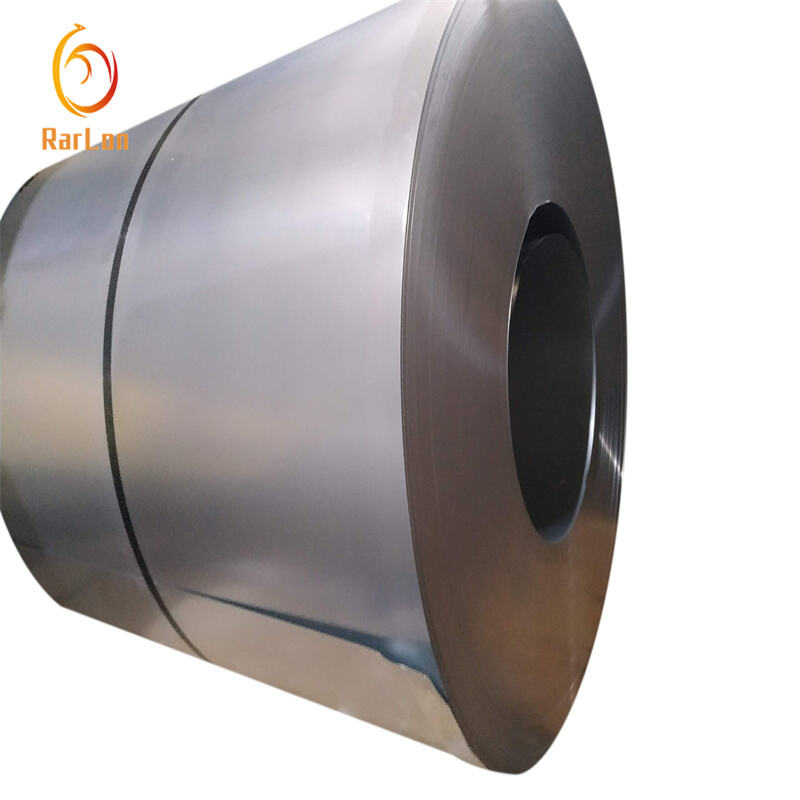

Unmatched Quality and Precision in Cold Rolled Steel for Automotive Manufacturing

Cold rolled steel is pivotal in automotive manufacturing due to its exceptional strength, precision, and surface finish. At China Rarlon Group Limited, we leverage advanced production techniques to ensure our cold rolled steel meets stringent automotive industry standards. Our products exhibit superior dimensional accuracy, making them ideal for various automotive applications including body panels, frames, and structural components. The cold rolling process enhances the steel’s mechanical properties, resulting in improved formability and weldability, which are crucial for automotive manufacturing. With our extensive experience since 2008, we guarantee reliability and performance, positioning us as a trusted partner in the global automotive sector.

Get A Quote