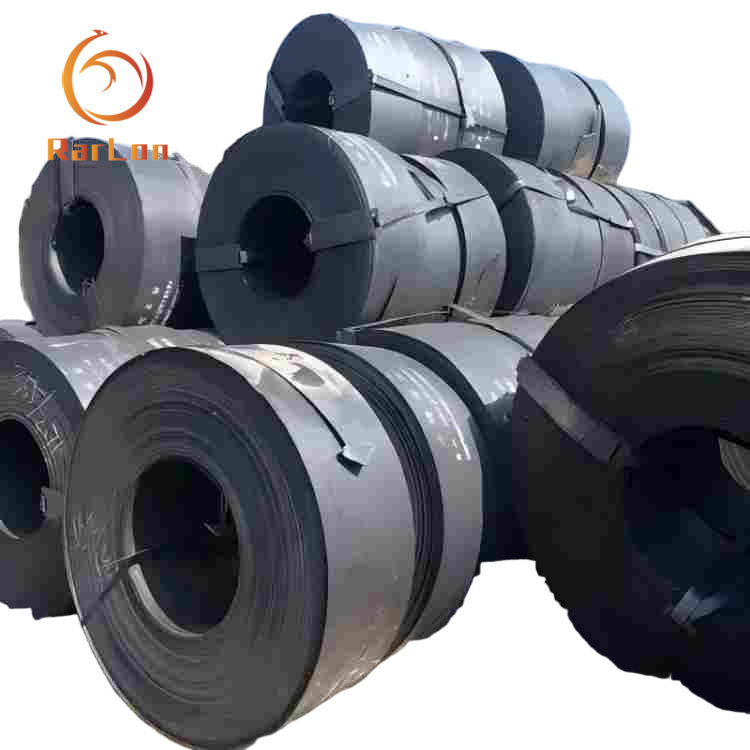

Hot dipped coils are used in construction and manufacturing as well as many other industries. As a value adding process to manufacture Hot Dipped Coated Steel Coils, Steel is dipped in a Zinc solution followed by a coating. This procedure increases the Steel’s resistance to rust and corrosion. This procedure is used on Hot Dipped Steel Coils for Steel that is used in hygroscopic and moist environments, especially Steel that is exposed to wet and harsh weather conditions. At China Rarlon Group Limited, we employ cutting edge technology in the manufacture of Hot Dipped Steel Coils and our quality control systems allow the coils to meets world standards. We also serve diverse clientele such as the construction industry, automotive industry, and agricultural equipment. Our clientele are provided with reliable and durable solutions. We have a proven history of honoring our clients’ specifications and transforming them into high quality products.

1116, Huaying Building Center Avenue, Tianjin Airport

+86-189 20578670

Copyright © China Rarlon Group Limited All Rights Reserved - Privacy Policy