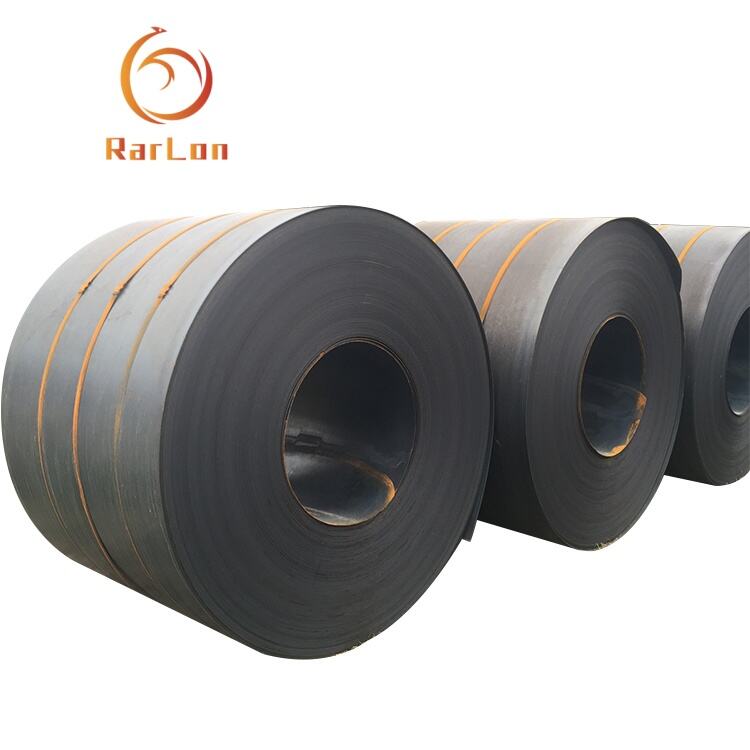

Exceptional Quality of Pickled and Oiled Steel Sheets

Our pickled and oiled steel sheets are manufactured using advanced techniques that ensure superior surface quality and excellent corrosion resistance. The pickling process removes impurities, rust, and scale, while the oiling provides a protective coating that prevents oxidation. This combination results in a product that is not only aesthetically pleasing but also highly durable, making it ideal for various applications in construction and manufacturing. Our commitment to quality ensures that each sheet meets international standards, providing you with reliable materials that enhance your projects.

Get A Quote