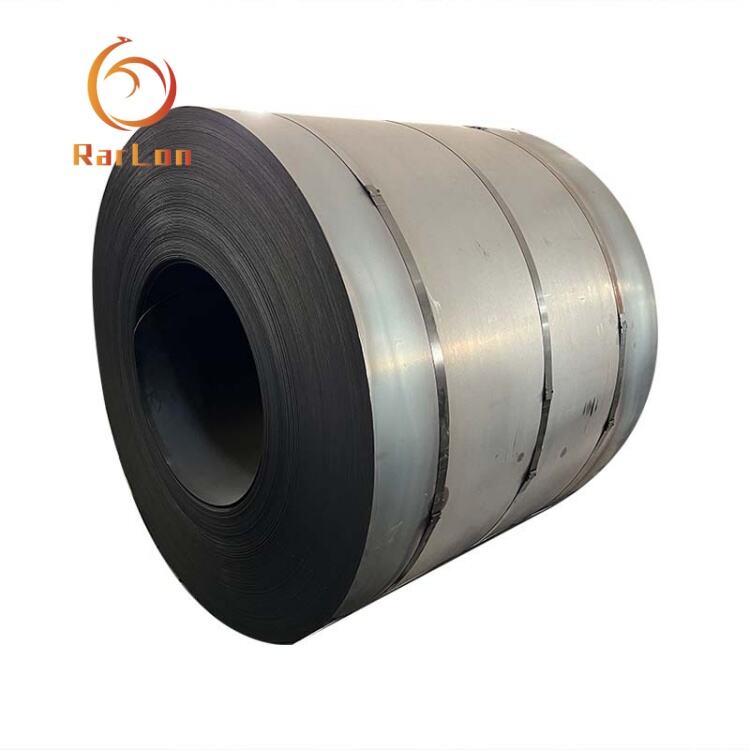

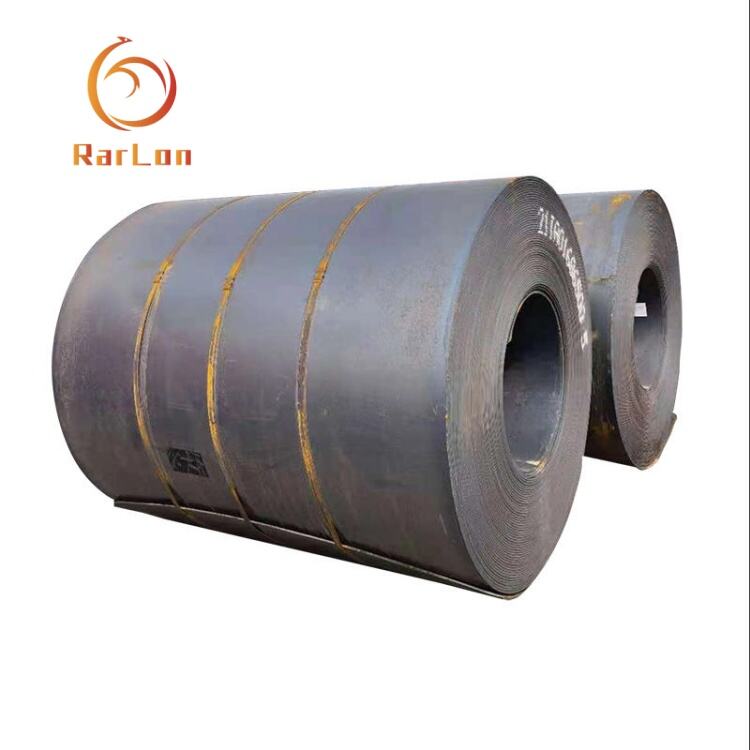

Hot Dipped Galvanized Steel Coils: Unmatched Durability and Versatility

Our Hot Dipped Galvanized Steel Coils are designed to provide exceptional corrosion resistance and longevity, making them ideal for various applications in construction and manufacturing. The galvanization process ensures a protective layer of zinc that significantly extends the life of the steel, reducing maintenance costs and enhancing structural integrity. With a focus on high-quality production and customer satisfaction, China Rarlon Group Limited leverages advanced manufacturing techniques to deliver products that meet international standards. Our steel coils are not only durable but also versatile, suitable for use in a wide range of industries including automotive, construction, and appliances.

Get A Quote