The Unmatched Benefits of Hot Dipped Galvanised Steel

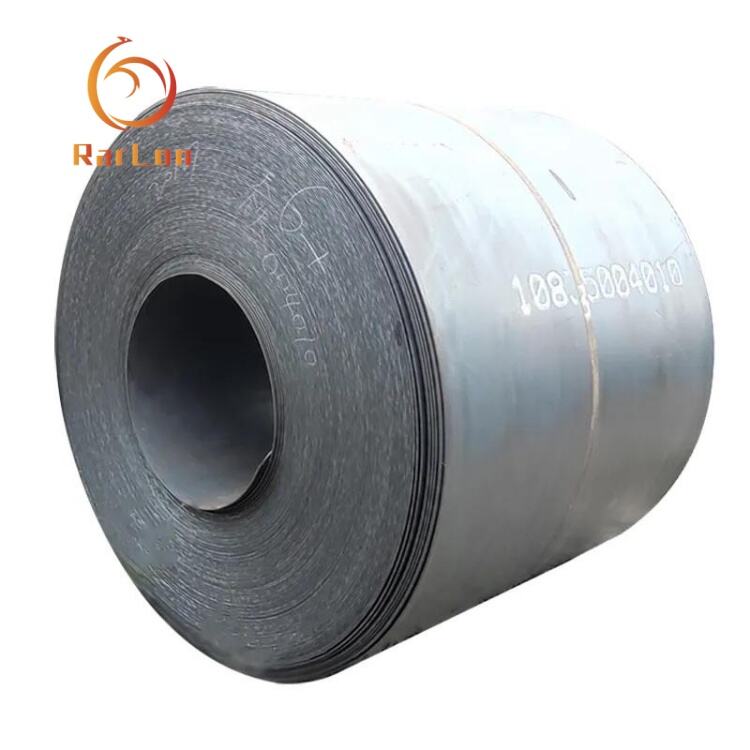

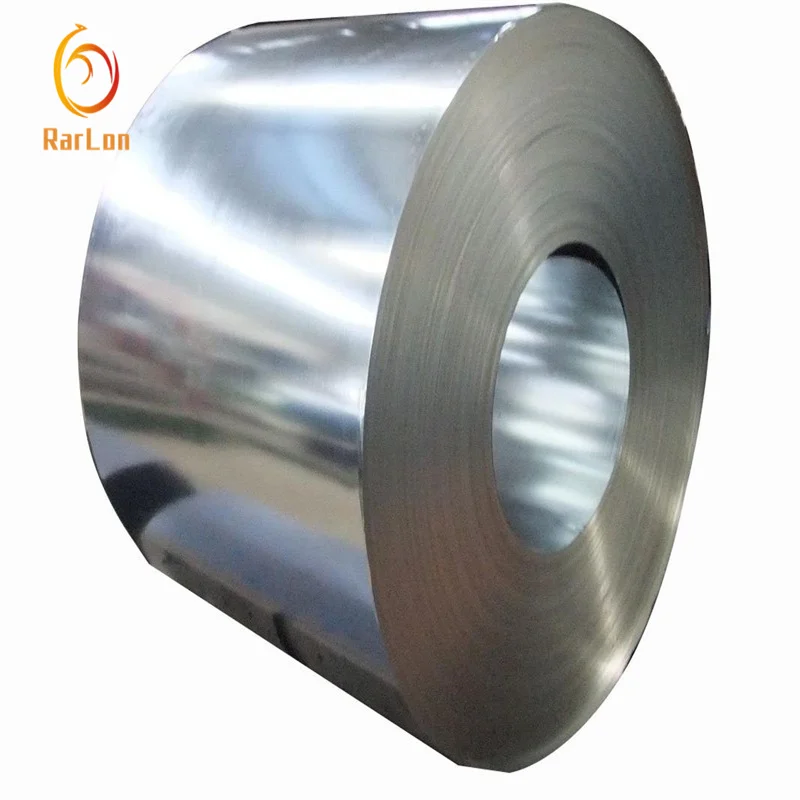

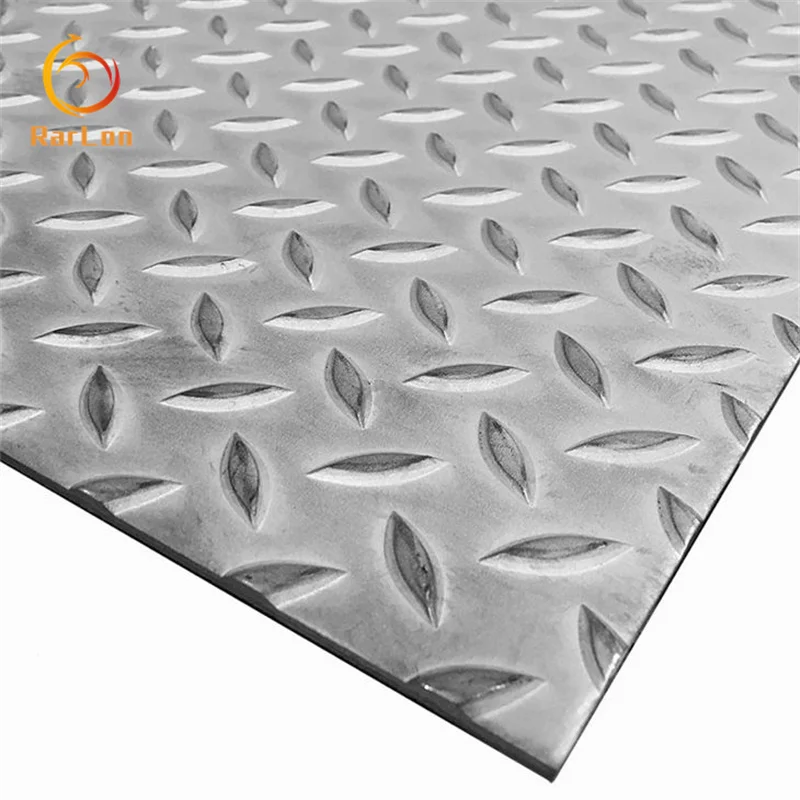

Hot dipped galvanised steel is renowned for its exceptional durability and resistance to corrosion, making it a preferred choice for various construction and industrial applications. The galvanisation process involves coating steel with a layer of zinc, which protects it from environmental factors and extends its lifespan significantly. This method not only enhances the aesthetic appeal of the steel but also reduces maintenance costs over time. Additionally, hot dipped galvanised steel offers superior strength and structural integrity, ensuring reliable performance in demanding conditions. With its ability to withstand harsh weather and resist rust, this material is ideal for outdoor installations, infrastructure projects, and heavy-duty applications, providing long-term value and reliability for customers.

Get A Quote

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RU

RU

ES

ES

TL

TL

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

SQ

SQ

HU

HU

MT

MT

TH

TH

TR

TR

FA

FA

MS

MS

MK

MK

HY

HY

AZ

AZ

KM

KM

LA

LA

MN

MN

MY

MY

KK

KK

UZ

UZ